Rubber solutions

Reliable and long-lasting

in any situation

We have the engineer team and machinery to offer you the best solution with all the guarantees that you seek.

Closed and semi-closed cell

sponge rubbers

[+ information]

Compact rubber stops/buffers

and bumpers

[+ information]

Recycled tire rolls,

tiles and parts

[+ information]

Large-scale

rubber parts

[+ information]

Thermoplastic foam

transformation

[+ information]

Manufactured compact polyurethane rollers and sheets

[+ information]

Projects

Our flexibility is far-reaching:

discover the projects that we have already implemented in over 30 countries.

CACESA RUBBERS – RUBBER MANUFACTURER

CACESA is a rubber factory dedicated to manufacturing solid and sponge rubber parts. Among the products they manufacture, elastomeric supports stand out, which are rubber pieces that absorb vibrations and expansions in metal or concrete structures.

They also produce:

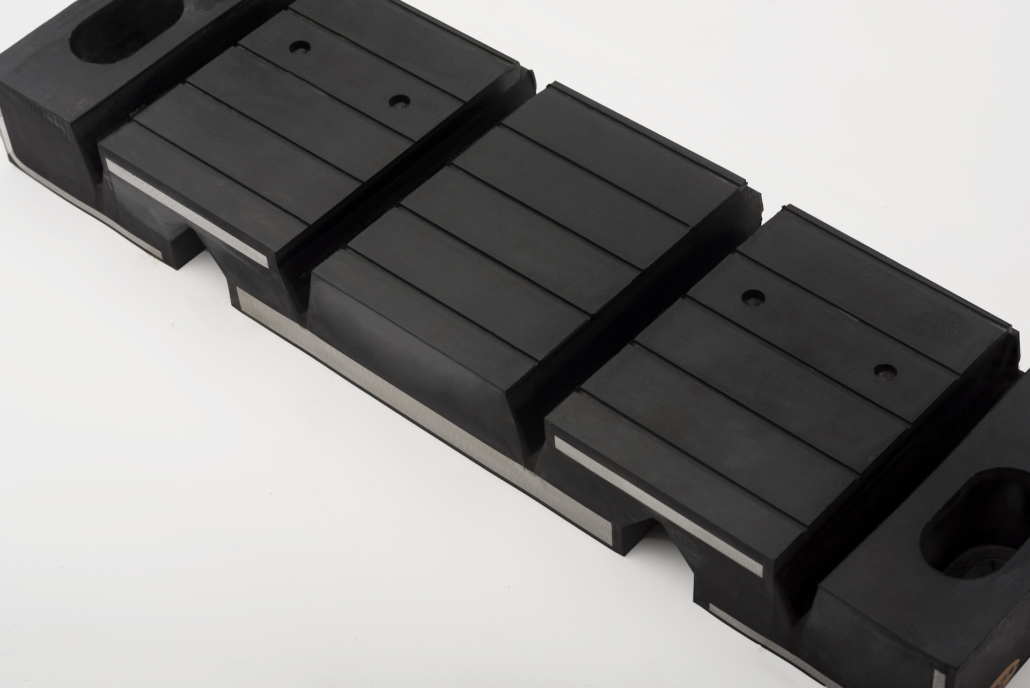

- Elastomeric supports

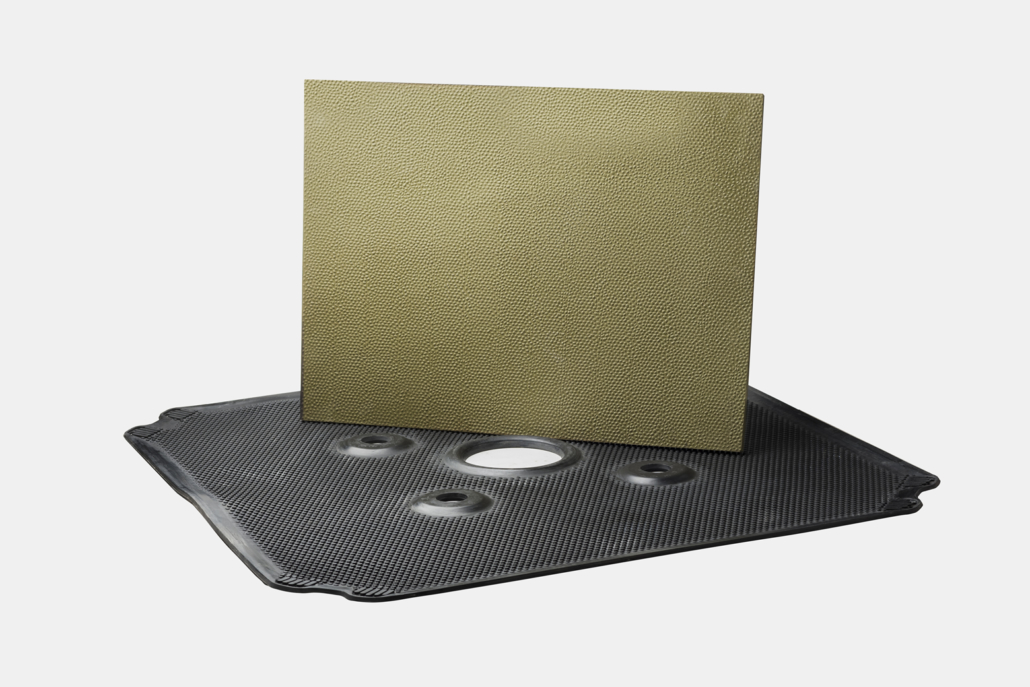

- Expansion joints

- Open-cell and closed-cell sponge rubber

- Truck stops, compact rubber bumpers

- Rolls, tiles, and recycled tire parts

- Large-sized rubber pieces

- Transformation of thermoplastic foams

- Manufacture of compact polyurethane in rollers and sheets

Elastomeric supports are manufactured using rubber and steel, and their function is to absorb movements and vibrations to protect the joints between different structures made of different materials.

In Spain, there are mandatory regulations for building in seismic risk areas. In other areas, they are not mandatory, but many structures, such as large shopping centers and warehouses, use elastomeric supports between the supports to comply with regulations and prevent damage in the event of an earthquake.

CACESA works for major Spanish construction companies such as ACS, Dragados, Constructora San José, FCC, ACI, Mekano4, Trelleborg, among others.

There are two types of elastomeric supports: unarmed ones, which are used for small movements, and reinforced ones, which include metal.

The service life of an elastomeric support depends on several factors, such as its manufacturing, installation, and quality of materials. Although a specific service life is not legally required, a well-manufactured and properly installed support can last between 50 and 100 years.